Electrical tape is not waterproof.

It is very elastic, and can stretch tightly around hoses and seems to seal tightly, but it can’t hold any pressure (it will stretch and the water will get past the seal).

Electrical contractors have a large assortment of watertight boxes, conduit, and protocols for wet environments. Some are required for code compliance and safety. Plumbers use watertight fittings everywhere, and have flexible options and sealants that are readily available at supply houses. If you are concerned, get an opinion from a tradesman or counterman before you make any repairs. If all you have is electrical tape, only use it in a non-pressurized environment – and only as a temporary last resort!

Depending on what you are using it for, there are tapes that have great water-resisting properties.

Since I have worked on boats in the past, I used a lot of heat shrink tape that could seal electrical cables, etc. most common is 3M Scotchrap All-Weather Corrosion Protection Tape, 2-Inch by 100-Foot, available from Amazon and most marine stores.

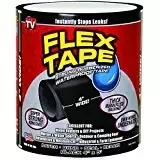

Most popular in the “infomercial” circuit is “Flex Seal”.

It comes in Black and white, and has an adhesive backing that can really resist water – even seal a hole in a bucket underwater! You can get it at Home Depot, Lowes, most big hardware chains, and Amazon.

You can also get Liquid electrical tape, which brushes on and seals electrical cables and connections. I used to use it under shrink wrap tape to make a very water resistant seal on spliced cables.

You also should consider Crimping, not soldering wires that are in a wet environment, as the flux may accelerate corrosion. Flux is an acidic cleaner that breaks down dirt on connections so the solder will adhere. I use crimps extensively when fixing wires on boats – makes a metal to metal connection. This is a good crimping kit from Amazon, all the big hardware stores carry them. Watertight connections are also important on cars, especially headlights, trailer connections, and wiring that can be exposed to rain and road contaminants.

To recap, use waterproof and not water-resistant tapes; seal out all air and moisture; crimp, twist, or solder joints; cover with liquid electrical tapeor heat-shrink tubing, and enjoy a water-tight connection!

Good luck and power on!